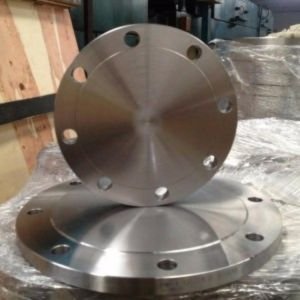

Veer Flanges is a leading manufacturer of GOST 33259 flanges, proudly based in Kolkata, India. These flanges are well-known for their accuracy and reliability, built to comply with rigorous GOST standards. They deliver exceptional strength and corrosion resistance, making them ideal for a variety of industrial applications. You can find GOST 33259 flanges in different sizes and pressure ratings, perfect for oil and gas pipelines, petrochemical operations, factories, and power plants. They’re particularly suited for critical systems. We are committed to using quality materials and ensuring durability, design accuracy, and performance, providing solutions that meet the diverse needs of businesses around the world.

GOST 33259 flanges are usually made from carbon steel, stainless steel, or various steel alloys. They contain a mix of alloying elements like carbon, manganese, and silicon, which help them achieve impressive strength and resist corrosion. These flanges boast solid mechanical properties, with tensile strengths ranging from 400 to 600 MPa and yield strengths between 250 and 350 MPa, allowing them to endure stress for longer periods.Some of the major advantages include exceptional durability, precise engineering, and the ability to handle high pressure and temperature scenarios. Their solid design not only guarantees strong connections but also makes installation straightforward, making them a top choice for critical applications in fields like oil, gas, petrochemicals and electricity generation.

| Standard | GOST / ГОСТ 33259 |

| Size | 1/2″ to 48″ |

| UNI | 6Bar 16Bar 10Bar 25Bar 40Bar |

| Class | 300 LBS, 150 LBS, 900 LBS, 600 LBS, 1500 LBS, 2500 LBS |

| EN | 6Bar 25Bar 10Bar 40Bar 16Bar |

| Flanges Face Type Provided By Manufacturer | RF (Raised Face), RTJ (Ring Type Joint) |

| BS | BS4504 , BS4504, BS1560, BS10 |

| Value Added Services | CNC Machining, Customised Flanges |

| Outer diameters | 1/2” to 24” |

| Making Methods Provided By Manufacturer | Casting And Forging Rolling And Cutting |

| JIS | 5K, 16 K 10 K, 20 K, 40 K, 30 K, 63 K |

| Flanges Test | Hydrostatic testing machine/ UI trasonic flaw detector/ X-ray detector/ Direct-reading Spectrograph/ Magnetic particle detector |

| Coating/Surface Treatment By Manufacturer | Antirust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| Flanges Equipment | Pushing Machine/ electric bevelling machine/ Press machine/ Bending machine/ Sand-blasting machine etc |

| Standards Provided By Manufacturer | BS4504, BS 10, API7S-15, JISB2220, BS1560-3.1, ANSI/ASME B16.5/16.36/16.47A/16.47B, EN1092, DIN, API7S-43, API605, B16.48, ISO70051, MSS S44 |

Veer Flanges a leading supplier in Kolkata, India, offers an extensive selection of GOST 12821-80 Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

The GOST 33259 flange is widely utilized in various industrial applications that require dependable and sturdy connections. You’ll usually find them in oil and gas pipelines, petrochemical plants, power generation facilities, and chemical processing operations. These flanges create safe, watertight joints for transporting liquid gases and hot water, even under high pressure and temperature conditions. They are crucial in heat exchangers, valves, pumps, and compressors, ensuring that everything operates safely and efficiently. Additionally, their design allows for easy maintenance and disassembly, making them a popular choice in demanding industries that value durability, safety, and reliable performance in harsh working conditions.

| Diameter conditional (DN), millimeter | O.D. Of (D), millimeter | Diameter of spacing (D0), millimeter | Diameter internal (dB), millimeter | Flange wall thickness (b), millimeter | fastener Size (d0), millimeter | mounting holes Number (n), pcs | Weight of one flange, kilogram |

| 15 | 80/95 | 55/65 | nineteen | 10/10 | 11/14 | 4/4 | 0.3 / 0.5 |

| 20 | 90/105 | 65/76 | nineteen | 12/12 | 11/14 | 4/4 | 0.5 / 0.7 |

| 25 | 100/115 | 75/85 | nineteen | 12/12 | 11/14 | 4/4 | 0.6 / 0.9 |

| 32 | 120/135 | 90/100 | 39 | 13/14 | 14/18 | 4/4 | 1.1 / 1.4 |

| 40 | 130/145 | 100/110 | 46 | 13/15 | 14/18 | 4/4 | 1.2 / 2 |

| 50 | 140/160 | 110/125 | 59 | 13/15 | 14/18 | 4/4 | 1.3 / 2.1 |

| 65 | 160/180 | 130/145 | 78 | 13/17 | 14/18 | 4/4 | 1.6 / 2.8 |

| 80 | 180/195 | 150/160 | 91 | 15/17 | 18/18 | 4/4 | 2.4 / 3.2 |

| 100 | 205/215 | 170/180 | 110 | 15/19 | 18/18 | 4/8 | 2.8 / 4 |

| 125 | 235/245 | 200/210 | 135 | 17/21 | 18/18 | 8/8 | 3.8 / 5.4 |

| 150 | 260/280 | 225/240 | 161 | 17/21 | 18/22 | 8/8 | 4.4 / 6.6 |

| 200 | 315/335 | 280/295 | 222 | 19/21 | 18/22 | 8/8 | 5.9 / 8 |

| 250 | 370/390 | 335/350 | 273 | 20/23 | 18/22 | 12/12 | 7.6 / 10 |

| 300 | 435/440 | 395/400 | 325 | 20/24 | 22/22 | 12/12 | 10.2 / 13 |

| 350 | 485/500 | 445/460 | 377 | 22/24 | 22/22 | 12/16 | 12.6 / 16 |

| 400 | 535/565 | 495/515 | 426 | 24/26 | 22/26 | 16/16 | 15.2 / 21 |

| 500 | 640/670 | 600/620 | 530 | 25/28 | 22/26 | 16/20 | 19/28 |

| 600 | 755/780 | 705/725 | 630 | 25/31 | 26/30 | 20/20 | 26/40 |

| 800 | 975/1010 | 920/950 | 820 | 27/37 | 30/33 | 24/24 | 46/79 |

| 1000 | 1175/1220 | 1120/1160 | 1020 | 31/43 | 30/33 | 28/28 | 64/118 |

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Veer Flanges, All rights reserved