Veer Flanges, established over the past 20 years, is the premier manufacturer and distributor of P250GH flanges for industrial pressure systems. P250GH flanges have been engineered to be very durable with high temperature capabilities and a track record of proven performance for over 25 years. Hudson’s P250GH flanges are produced to the highest standard, and can be used in a variety of applications including, pipelines, boilers, pressure vessels, and other pressure equipment. Veer Flanges takes pride in their own experience and strive to produce high-quality, dependable products that are sold into a variety of industries, including oil and gas, chemical, power generation, and more, for over 25 years. If you choose to work with Veer Flanges, you are choosing to receive solutions that have been designed and engineered to minimize risk, improve productivity and performance, and give customers a long-term feeling of safety in their project.

P250GH flanges are made from a carbon steel family. Carbon steel is an alloy with carbon, manganese, silicon as the predominant elements and can therefore provide a high degree of durability and strength. They have excellent mechanical properties, including high ultimate tensile strength, good weldability, and resistance to elevated temperatures and pressures. P250GH flanges have many features that are advantageous, including better toughness in extreme conditions, affordability, and compatibility with high pressure and high-temperature operations. For these reasons and others, P250GH flanges are particularly suitable for power generation, chemical processing, and oil and gas activities.

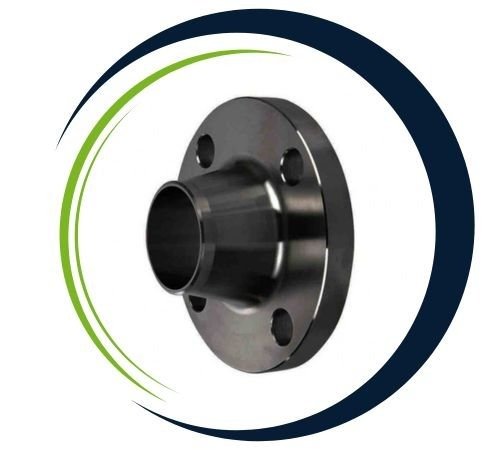

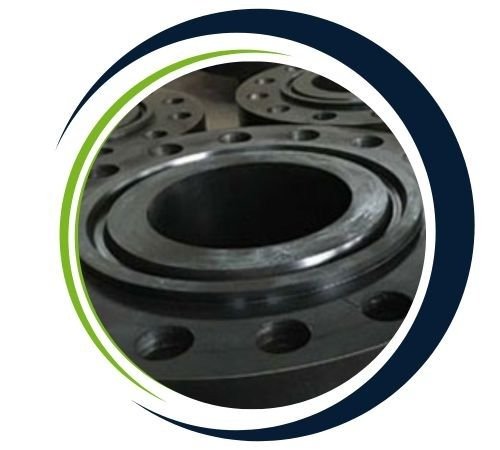

Veer Flanges, a leading supplier in Kolkata, India, offers an extensive selection of P250gh Flange, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

| Size Chart | 1/2 inch (15 Nominal Bore) to 48 Inch (1200 Nominal Bore) |

|---|---|

| Pressure Rating ANSI | Class 600, 900, 150, 2500, 300, 1500 LBS |

| Pressure Calculation in DIN | 16, 6, 25, 40, 10 Bar / PN10 PN16 PN6 PN25 PN64 PN40 |

| JIS Standards | 5, 10, 16 20, 30, 40, 63 K |

| UNI Standards | 6, 10, 16, 25, 40 Bar |

| EN Standards | 6, 10, 16, 25, 40 Bar |

| Coating | Cold and Hot Dip Galvanized, Anti-rust Paint, Zinc Plated,Oil Black Paint, Yellow Transparent |

| Most common types | Screwed, Forged, Threaded, Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate Third Party Inspection Report , 100% Radiography Test Report etc |

| Production technique | Forged, Heat treated and machined |

| Flange Face Type | Small Tongue, Lap-Joint Face, Raised Face, Ring Type Joint, Flat Face, Large Male-Female, Small Male-Female, Large Tongue & Groove Flanges manufacturer and Supplier |

| Flanges Marking | All Flanges are marked as follows: Supplier or Manufacturer’s Name, Size, Class, Bore, Dimension, Material, Heat No. Or according to the customer’s request. |

| Test | Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Direct-reading Spectrograph, Magnetic particle detector |

| Equipment | Bending machine, Sand-blasting machine, Pushing Machine,Press machine, electric bevelling machine etc |

| Carbon | Silicon | Manganese | Nickel | Phosphorus | Sulfur | Chromium | Vanadium | niobium | Titanium | Aluminum | – |

| 0.18 – 0.23 | max 0.4 | 0.3 – 0.9 | max 0.3 | max 0.025 | max 0.015 | max 0.3 | max 0.02 | max 0.01 | max 0.03 | 0.015 – 0.05 | Cr+Cu+Mo+Ni < 0.7 |

| Nominal thickness (mm): | to 150 | ||

| Rm – Tensile strength (MPa) (+N) | 410-540 | ||

| Nominal thickness (mm): | to 50 | 50 – 100 | 100 – 150 |

| ReH – Minimum yield strength (MPa) (+N) | 250 | 240 | 230 |

| KV – Impact energy (J) longitud., | +20° 47 | ||

| Nominal thickness (mm): | to 150 | ||

| A – Min. elongation at fracture (%) (+N) | 25 |

P250GH flanges are commonly encountered in a variety of industrial applications where high-performance, sturdiness at high temperatures, and high pressures are essential. Common industry applications for P250GH flanges are in power generation, oil and gas, chemical processing, and petrochemical. The high-capacity flanges can be used on pipelines, boilers, pressure vessels, and components that can experience extreme conditions. The flanges have great weldability and resistance to heat; therefore, it can securely attach pipes, valves, pumps to the system. P250GH flanges are particularly desirable in applications subject to stress, fatigue, and reliability under immense conditions. These accounts for safety and performance in an industrial environment.

Yes, we offer custom sizes for P250gh Flange to meet specific project needs. Our team at Veer Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@veerflanges.co.in.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Veer Flanges, All rights reserved